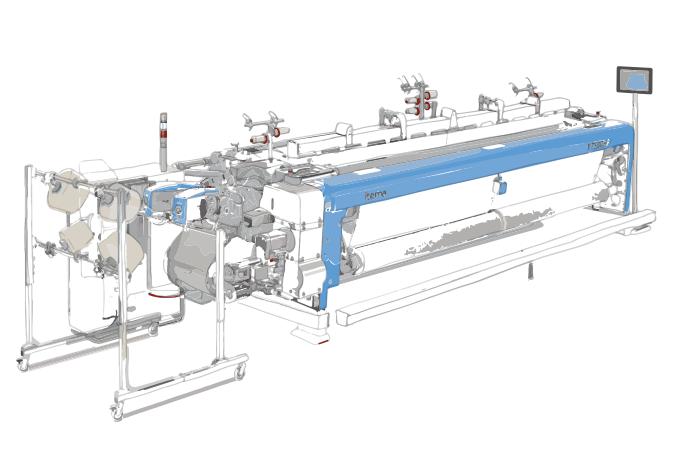

Textile Mastery:

Superior denim fabric quality with no compromises in terms of performance

The unmatchable uniqueness of the positive weft transfer consists of the single insertion driven by the projectile, which catches the weft and carries it directly with no exchanges, providing unmatched efficiency thanks to an insertion speed.

The shed geometry of P7300HP-V8 together with the optimized sley movement ensures top fabric quality, effectively avoiding start marks, even weaving delicate fabrics and making the Itema projectile weaving machine the preferred choice of weavers looking for top-quality fabrics, especially for technical fabrics and denim applications.

Moreover, the P7300HP represents an unbeaten and unbeatable benchmark for those looking to weave the very widest fabrics — the Itema projectile weaving machine is available in nine standard versions up to 655 cm.

The Unique-in-the-market Projectile Weft Insertion System

In the P7300HP-V8 the weft is guided in a positive controlled manner in every phase of weft insertion: from weft transfer to the projectile, passing through insertion into the shed, all the way through to beat-up. The optimized motion sequences and direct projectile acceleration result in a weft insertion rate of as much as 1570 m/min.

The projectile weaving machine reliably grips a wide variety of threads,tapes or monofilament yarn and inserts them into the shed. Projectile grippers with various clamping forces and surface areas are available to reflect the varying requirements for different weft yarns. One outstanding feature of projectile technology is that the weft is inserted without central transfer, avoiding additional acceleration and braking. With this unique insertion technology, the P7300HP-V8 inserts all weft yarns in a guided and controlled way with minimum yarn stress, ensuring maximum reliability in the production of high-quality fabrics. The new main drive of the P7300HP-V8 is a further point of excellence since it requires considerably less servicing andmaintenance thanks to the pneumatic clutch pressure system.

The WidestRange of Weaving Widths

The P7300HP-V8 is available in nine working widths, from 220 cm up to 655 cm. It is the only weaving machine in the market for which 655 cm is a standard width — a real advantage in many applications, and especially so in the production of technical fabrics where the P7300HP-V8 enables weaving agrotextiles and geotextiles in larger widths, requiring fewer or no seams. On models with large working widths, the efficiency of the P7300HP-V8 is further increased by its ability to weave several fabrics runs of the same or different widths simultaneously. As a result, the maximum weft insertion rate is attained at lower machine speeds, thus reducing machine wear, lowering space requirements and saving electricity.

The benefits offered by the P7300HP-V8 projectile weaving machine are multifaceted and include:

• lowest power consumption of all weaving systems

• tucked selvedges

• no warp and weft material wastage

• quick warp and style changing

• low spare parts consumption

• high reliability

• oil bath-immersed, practically maintenance-free sub-units, to name just a few.

Sturdy, High Precision Machine Frame

The P7300HP-V8 is the ultimate sturdy machine concept, made with side heavy-duty frames, built to bear high loads. The machine’s stability and reliability are further increased thanks to additional cross-support.

These features ensure the machine’s low vibration, allowing less wear and tear and guaranteeing the well-known excellence of textiles woven on projectile weaving machines.

Itema Shed Geometry

In developing the P7300HP-V8 , top fabric quality was our paramount goal which was achieved with a new shed geometry and an optimized sley movement.

The Itema projectile P7300HP-V8 produces fabrics of supreme quality, from all raw materials and for all applications. With a weft insertion rate of up to 1570 m/min,it is outstandingly cost-efficient. The famous projectile weft insertion technology is suitable for any weft material: spun yarns made of natural and manmade fibers, filaments or tapes.

Shed formation can befitted with either a tappet motion with up to 14 healdshafts or an electronically controlled dobby with up to 18 heald shafts. In combination with the colorselector, which can handle up to 6 weft colors, there are practically no restrictions or limits when it comes to weaving endless creative styles.

Technical Textiles: the specialty of the legendary P7300HP-V8

For decades, projectile weaving technology has been acclaimed as the leader in technical textile production, from the finest filter fabrics (bolting) up to ultraheavy coating fabrics (conveyor belts), all in outstanding quality. In the production of fabrics from polypropylene tapes, for big bags, carpet backing, geotextiles or agro textiles, the projectile weaving machine excels with unparalleled economy and quality.

P7300HP-V8 features modular design for special applications, which makes its versatility unrivaled: both in its standard equipment and in the many optional extras available.With accessories tailored to the application, it can be customized to meet the weavers’exact needs, including weaving extremely dense woven fabrics — up to 15,000 N/m, reed beat-up force — for filtrations, conveyors belts, geo reinforcement.

Superior Quality Denim Fabrics

When it comes to weaving technical textiles and high-quality denim fabric, the Itema projectile P7300HP-V8 is the best choice in the market. Denim fabrics are produced worldwide and with great success on our projectile weaving machines. One outstanding feature of the projectile technology is the exclusive opportunity to weave also the heaviest denim fabric, up to 14 1/2 oz., thus allowing the weaver to unleash his or her creativity in producing high-quality denim.